How do iron beams work

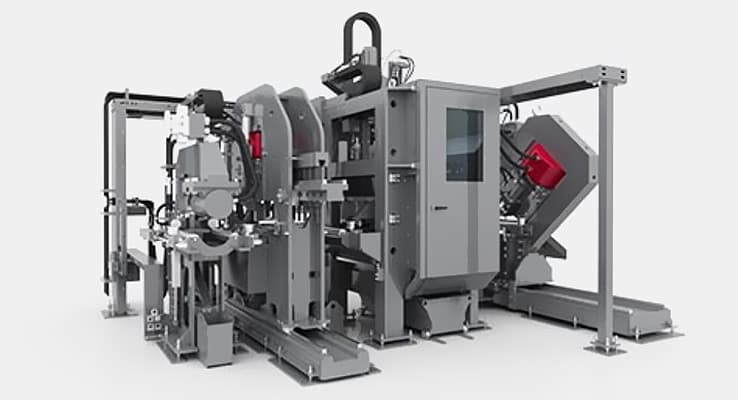

Now you can make custom beams without any delays. Beam Layout Welding can increase productivity in your business, both for straight beams and tapered beams. The beam layout welding automatically welds both of the beam's end flanges simultaneously, providing the penetration required on up to 1/2" web and 1 1/2" flange. It does this by using one pass from each side. The PHI system produces fillet welding between the web & flange. Construction codes require uniform welding.